Economical Strategies for Packaging Machine Repair and Upgrades

Economical Strategies for Packaging Machine Repair and Upgrades

Blog Article

From Advancement to Execution: Harnessing the Power of a Modern Packaging Device for Lasting Development

In today's dynamic organization landscape, the convergence of technology and sustainability has become a prime focus for business striving to remain eco liable and competitive. The fostering of modern-day packaging machines provides a significant chance for companies to improve procedures, lower waste, and enhance their total brand track record. The journey from conceiving ingenious product packaging options to successfully applying them in a way that drives sustainable growth is a complex procedure that calls for cautious factor to consider and calculated planning. By checking out the intricate relationship in between sustainability, innovation, and business success, we can discover the key techniques that will push enterprises towards a much more eco-conscious and flourishing future.

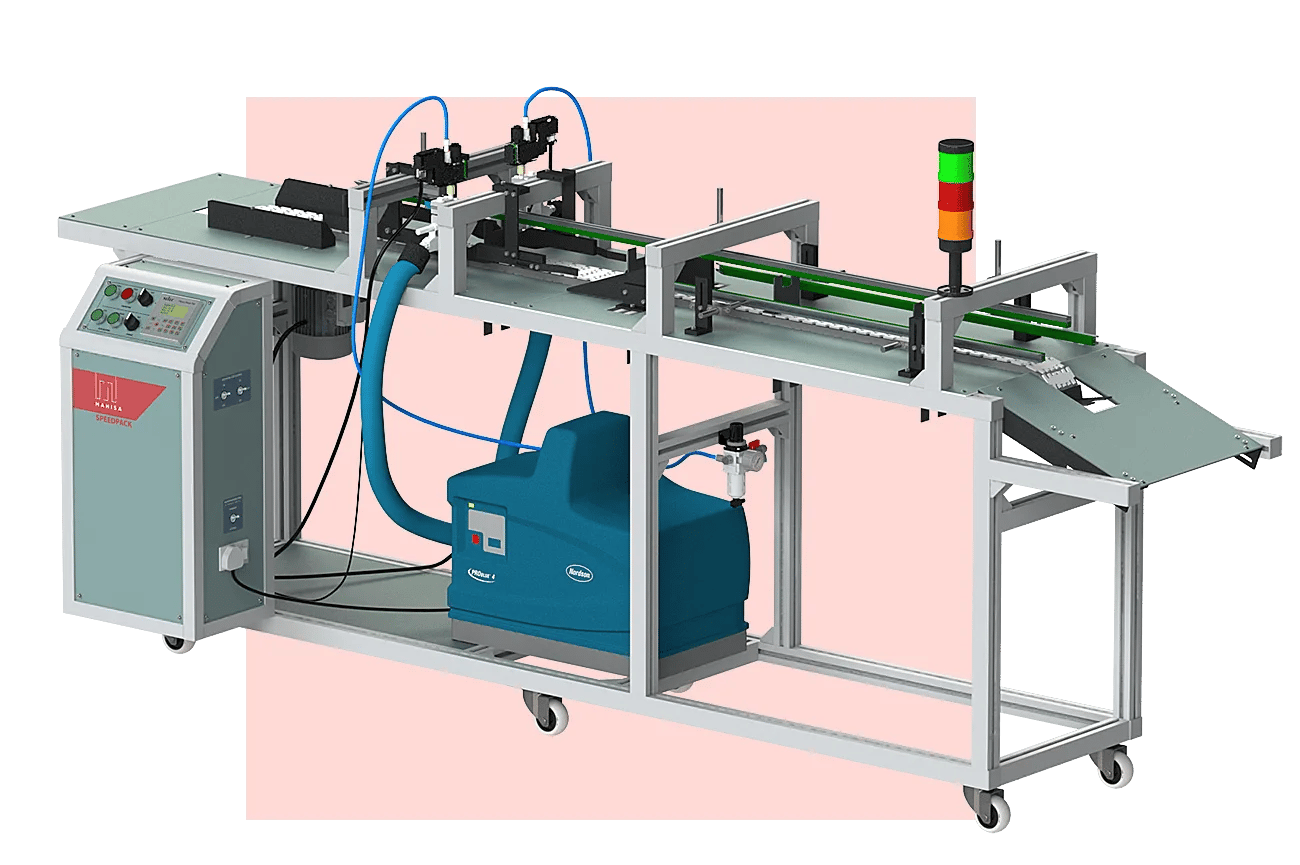

The Role of Modern Product Packaging Equipments

In today's hectic industrial landscape, modern product packaging makers play a crucial duty in improving performance, consistency, and cost-effectiveness in the product packaging process. These advanced machines are made to fulfill the growing demands of the market by improving procedures, minimizing downtime, and ensuring item high quality.

One trick aspect of modern product packaging equipments is their capacity to boost effectiveness. By automating numerous phases of the product packaging procedure, these devices can handle tasks at a much faster rate than hand-operated labor, leading to greater productivity levels. In addition, the consistency attained through automation makes sure that each item is packaged with the exact same accuracy and top quality, lowering the threat of errors or variances.

Cost-effectiveness is an additional significant benefit offered by modern product packaging machines. While the initial investment might be higher, the lasting financial savings in labor prices, lowered material wastage, and raised production output make these devices a wise financial investment for companies aiming to optimize their packaging operations. To conclude, the role of modern product packaging makers is essential in driving efficiency, consistency, and cost-effectiveness in today's packaging industry.

Benefits of Lasting Product Packaging Solutions

Utilizing lasting product packaging options provides a plethora of benefits for services intending to lessen their ecological effect while satisfying customer needs for green products. One essential advantage is the decrease of carbon footprint. Lasting packaging typically involves making use of recyclable materials, biodegradable options, and minimized product packaging waste, leading to lower greenhouse gas emissions and overall environmental influence. In addition, adopting lasting packaging options can enhance brand name reputation and customer commitment. In today's eco mindful market, consumers are increasingly favoring products that are packaged sustainably, demonstrating a commitment to ecological stewardship. This can cause an affordable edge for services that prioritize sustainability in their packaging practices. Sustainable product packaging options can lead to set you back savings in the lengthy run. While first financial investments might be required to transition to sustainable products and methods, performances acquired through reduced product use, go to this web-site transport expenses, and waste management expenses can add to total expense decreases gradually. Overall, accepting sustainable product packaging remedies not just profits the planet but also supplies calculated advantages for companies seeking to flourish in an extra eco-conscious market.

Implementing Green Practices in Manufacturing

The combination of eco conscious practices in manufacturing procedures is critical for modern businesses making every effort to More Bonuses reduce their eco-friendly impact. Applying eco-friendly practices in manufacturing involves adopting strategies that lower waste, energy consumption, and general environmental influence. One crucial element is the use of sustainable power sources such as solar or wind power to operate machinery and power manufacturing processes. In addition, carrying out reusing programs within the production center can aid minimize the amount of waste sent to landfills.

Another critical element of green production practices is the optimization of sources via reliable procedures and modern technologies. This consists of using advanced product packaging makers that are developed to reduce material usage while preserving item stability. Utilizing lean production concepts can also add to decreasing waste and boosting overall effectiveness in manufacturing procedures.

Furthermore, integrating lasting products right into the manufacturing procedure, such as biodegradable product packaging products or recycled material, can better boost the environmental sustainability of the company. By incorporating these eco-friendly techniques right into manufacturing processes, services can not just minimize their ecological influence however likewise show a commitment to sustainability that resonates with eco-conscious customers.

Enhancing Efficiency Through Technological Innovation

Additionally, the execution of smart innovations, such as Net of Points (IoT) data and sensors analytics, permits for real-time surveillance of packaging procedures. This not only makes it possible for positive maintenance to stop downtime however also offers useful insights for maximizing workflows and resource usage. In addition, making use of robotics in packaging operations can better boost efficiency by dealing with repetitive jobs with accuracy and uniformity.

Lasting Development Methods With Packaging Innovation

In enhancement to environmental benefits, lasting product packaging methods can also lead to cost financial savings in the long run. Overall, the critical combination of additional info sustainable product packaging technology is not just beneficial for the planet however additionally for long-term organization growth and success.

Final Thought

In verdict, the duty of modern-day product packaging makers is indispensable in driving efficiency, uniformity, and cost-effectiveness in today's product packaging industry. - packaging machine repair

Lasting product packaging commonly involves the usage of recyclable products, biodegradable alternatives, and decreased product packaging waste, leading to lower greenhouse gas exhausts and overall ecological effect.Applying lasting growth strategies through the combination of innovative product packaging modern technology is critical for companies aiming to decrease ecological effect while increasing functional efficiency and profitability.In conclusion, modern product packaging equipments play an essential function in driving lasting development by using advantages in performance and green methods. By applying technological innovation and sustainable packaging remedies, organizations can improve their production procedures and add to a much more environmentally pleasant future.

Report this page